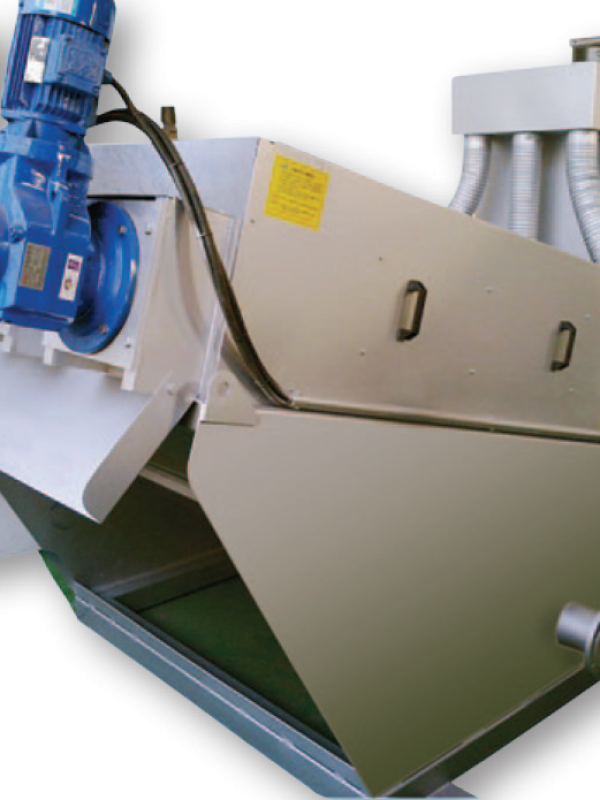

TRIDENT MD Press

Description

The TRIDENT MD Press has been designed to handle a wide range of sludge types and field applications. It is especially useful when sludge has a high oil and fat content (FOGS) that would bind filter materials and clog the process. The TRIDENT MD Press is designed to achieve both thickening and dewatering of sludge in a single operation. Significant cost benefits are achieved because the TRIDENT MD Press can process sludge directly from the aeration tank, eliminating capital costs for storage and thickening as well as reducing processing time and operational costs. Constructed from 304 stainless steel and other high quality non-corrosive components the TRIDENT MD Press will provide long life and trouble free operation. Completely automated the MD Press can perform as a standalone component with a dedicated control panel or be integrated into any existing system.

Features

- 304SS construction

- CIP Spray Bar

- Moving Rings

- Low HP

- Dry Nutrient Rich Cake

- Floc tank available

Benefits

- Totally automated efficient operation

- Long lasting & corrosion resistant

- Produces high-quality filtrate, simple & effective operation

- Extremely low power consumption–up to 95% less than many other dewatering processes

- Low noise and reduced odor generation

- Able to handle oily sludge

- Built-in flocculants dosing function

Typical Applications

Wastewater sludge thickening

Wastewater sludge dewatering

Effluent nutrient recovery

Food processing wash down waste removal

Trident Wave Separator

Description

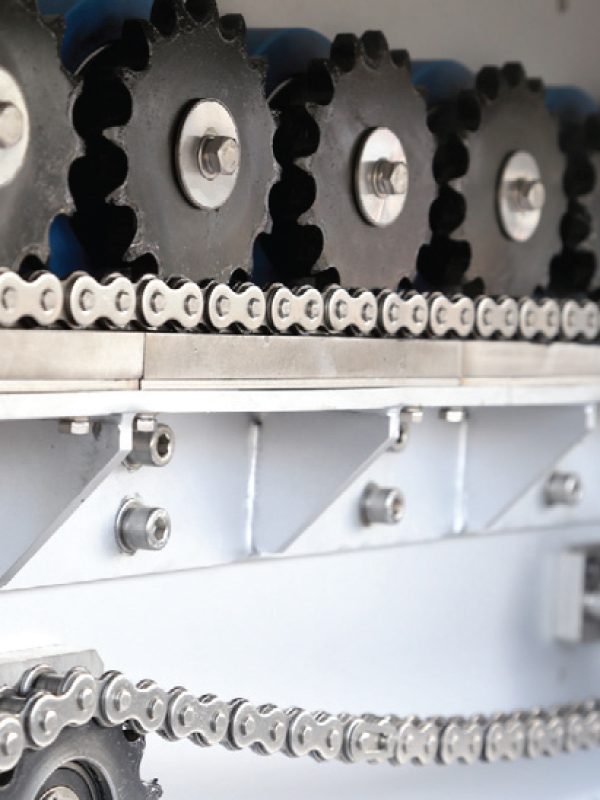

The TRIDENT Wave Separator is a unique material separation technology that offers a very effective alternative to conventional solid/ liquid separation systems. It provides very effective material separation, a small footprint and very low opex superior to centrifuge or belt press technologies. The Tride nt Wave Separator is scalable to suit multiple applications and varying volumes of material. Constructed from 304 stainless steel and other high quality non-corrosive components the Tride nt Wave Separator will provide long life and trouble free operation. Completely automated the Wave Separator can perform as a standalone component with a dedicated control panel or be integrated into any existing system.

Features

- 304SS construction

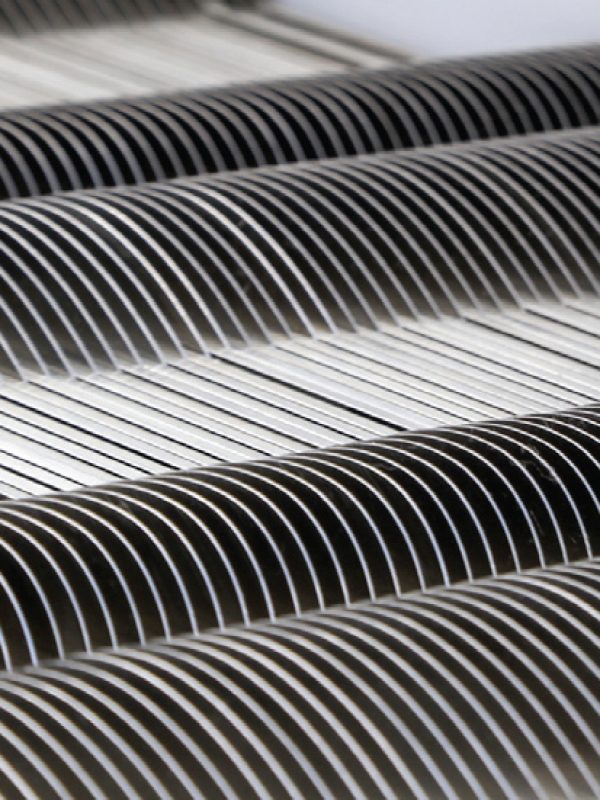

- Moving discs

- Low HP

- Variable Speed Drive

- Self cleaning

- Floc tank available

Benefits

- Self cleaning design, produces high-quality filtrate, does not need to return to the headworks (i.e. high solids recovery) and very low maintenance

- Extremely low power consumption–up to 95% less than many other dewatering processes

- Custom processing speeds/efficiencies

- Low wash water consumption

- Built-in flocculants dosing function

- Able to process a variety of feedstocks including oily sludge

Typical Applications

Wastewater sludge thickening

Wastewater sludge dewatering

Effluent nutrient recovery