The Screwtech range of screw conveyors are proven and a reliable method to convey bulk, irregular or difficult conveyed product, varied flow rates and consistency makes Screwtech equipment ultra-reliable in even the most demanding applications.

The Screwtech family of screw conveying equipment incorporate a range of standard components to form a single stand-alone conveyor or a complete conveyor system enabling single source supply and responsibility of all system components.

Our expertise acquired over the years has enabled Concept Solutions to apply this knowledge to many screw conveying processes which results in the best selection for an application, superior quality and competitively priced screw conveyors or conveyor systems.

Typical Applications

Municipal sludge, screening, grit

Industrial waste applications

Food & Beverage processors

Compost and fertiliser processors

Bulk materials

Screwtech Equipment

Screwtech Shaftless Screw Conveyors

Conveyor Type

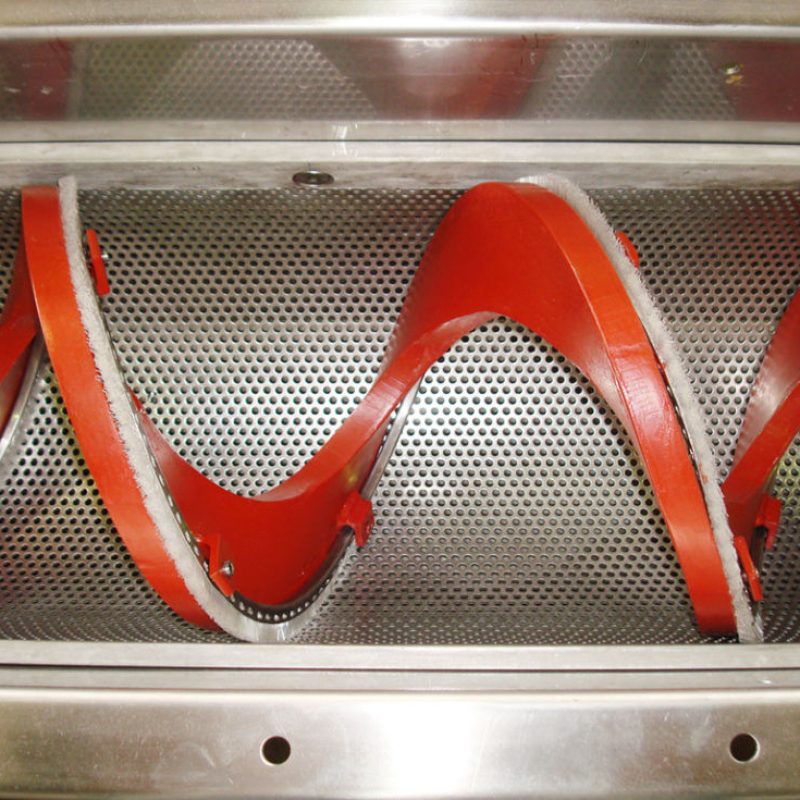

As the name suggests a Shaftless Screw Conveyor is without a core and driven directly to the helix rather than via a central shaft. The helix is far heavier and manufactured of a higher tensile strength material compared to shafted screws. Shaftless Screw Conveyors are typically direct drive and run on the lined casing and without hanger or tail end bearings.

Typical Applications

Plug and arch forming products such as dewatered sludge, screenings and offal

Irregular products such as slaughterhouse carcasses, heads, bones and waste

Grains, Ash, Sand, marc, soil and sawdust

Difficult inconsistent materials and variable flow rates

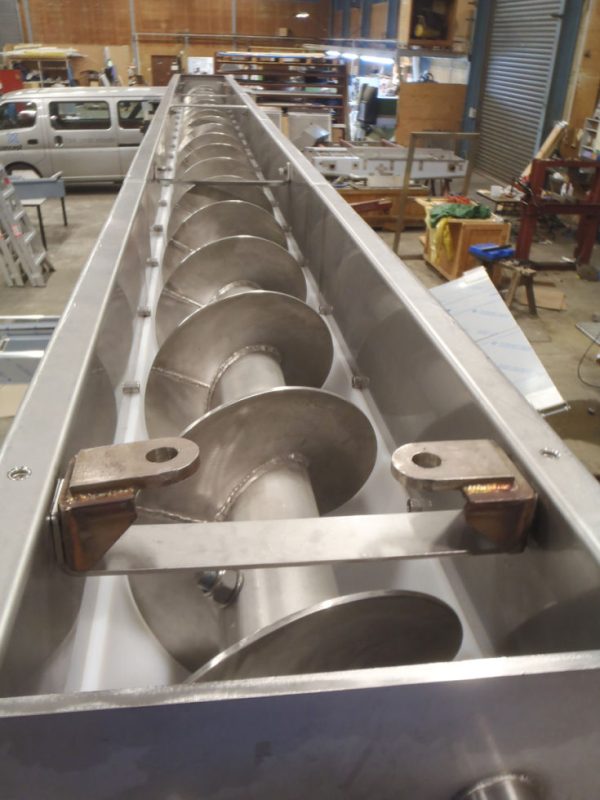

Screwtech Shafted Screw Conveyors

Conveyor Type

In addition to Shaftless Screws, Screwtech also design and manufacture standard shafted screw conveyors for general purpose applications. Where products aren’t considered as difficult to convey, shafted screws are often used.

Typical Applications

Industrial waste applications

Food & Beverage processors

Compost and fertiliser processors

Bulk materials

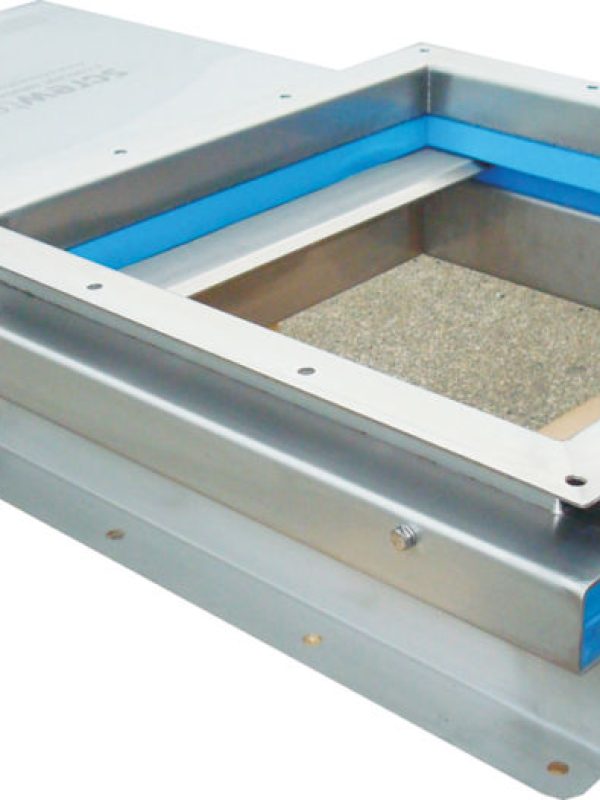

Screwtech Slidegates and Diverter Chutes

Screwtech Shafted Screw Conveyor

Conveyor Type

The ScrewTech range of Slidegates and Diverter Chutes provide control and isolation of material flow within a screw conveying system or hopper/tank outlet.

Our slidegate valves utilise a one-piece water and odour tight polyurethane moulded cartridge seal, acting against a sliding knife gate. This gate can be manually, electronically or pneumatically activated.

The diverter chutes provide the ability to split or redirect product flow to duty or standby equipment. A hinged flap provides the direction within the chute which can be manually, electronically or pneumatically controlled.

Typical Applications

Slide gates for flow diversion or isolation

Diverter chutes to transfer product between equipment

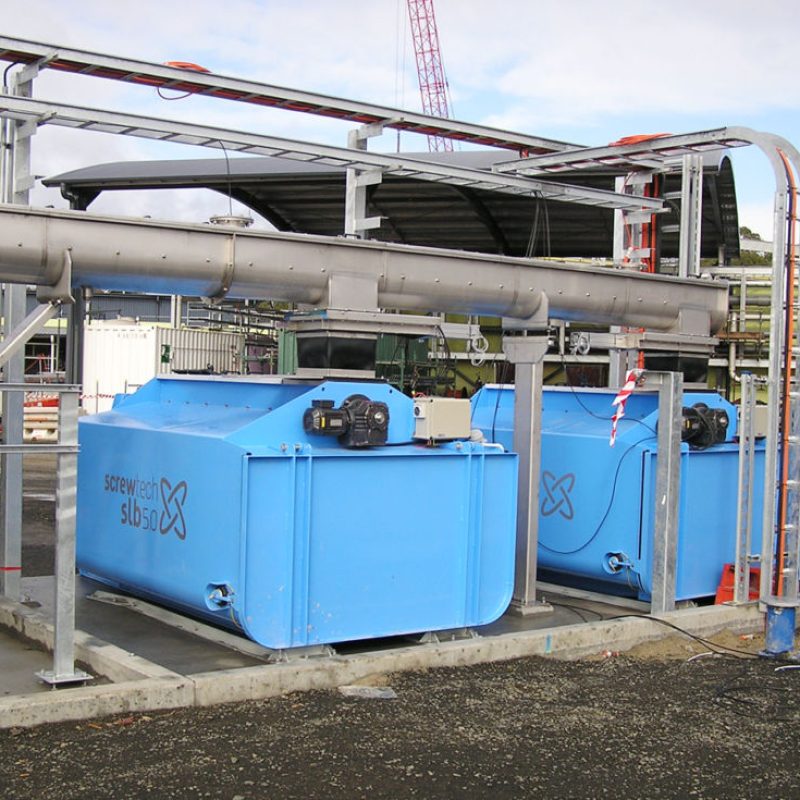

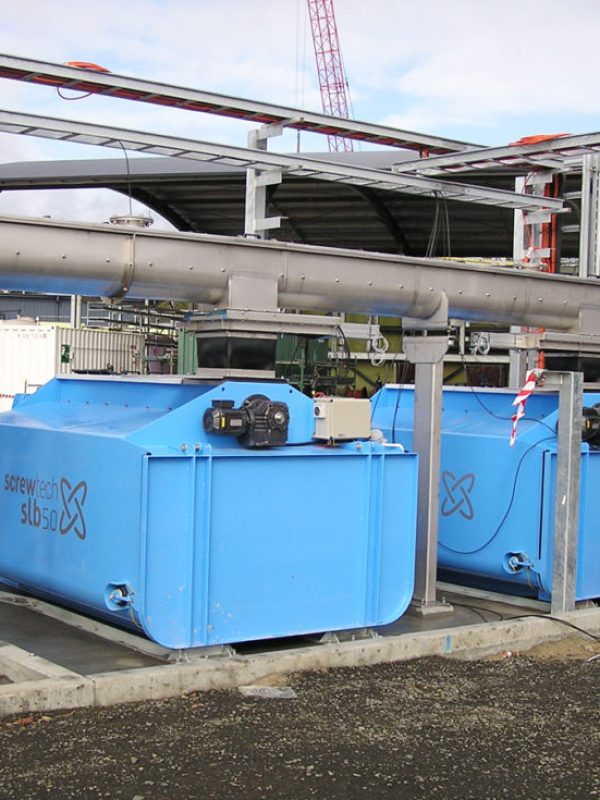

Screwtech Self Levelling Bins

Conveyor Type

A Screwtech SLB Bin is a filling/storage system for biosolids collection. The product is conveyed along the length of the SLB Bin by an integral Screwtech shaftless screw conveyor which fills the bin to its optimum level via a series of cut-outs and stops automatically when full. This enables the SLB Bin to be lifted or rolled onto a vehicle for disposal. The SLB Bin is fully enclosed with a hinged sealed tail gate for emptying by way of the hook-lift truck. This ensures zero spillage and full odour containment during operation and transport. The bins are built in a range of capacities.

Typical Applications

Storage of grit, dewatered screenings, dewatered sludge

Food production waste

Slaughterhouse waste

Organic waste

Biosolids

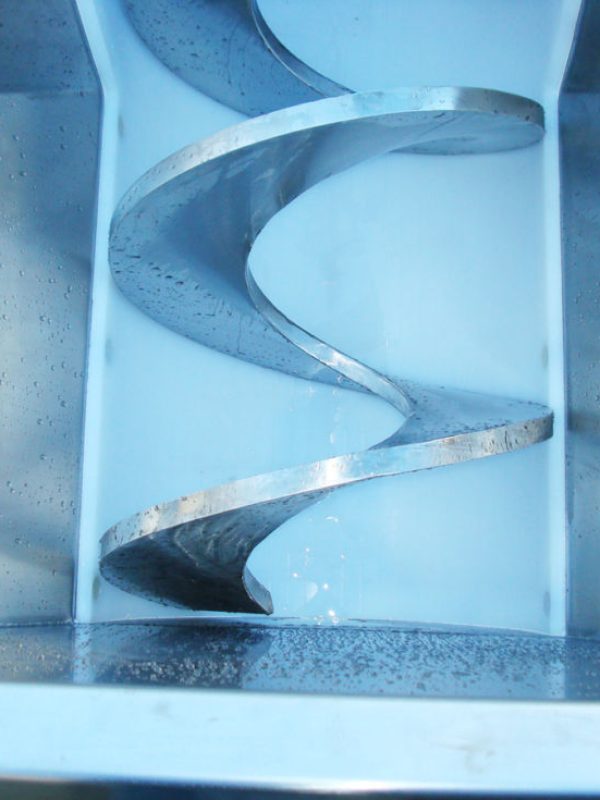

Screwtech Live Bottom Feeders

Conveyor Type

Live bottom bins or hoppers are used for the storage and metered feeding of product to downstream equipment. ScrewTech Live bottom feeders are ideal for handling difficult products which are prone to bridging or binding such as granular wood chip and waste sludge or screenings. ScrewTech LBF’s can be manufactured in either Mild or Stainless Steels and in Shaftless or Shafted screw options to suit the specific application and environment.

Typical Applications

Storage of grit, dewatered screenings, dewatered sludge

Food production waste

Slaughterhouse waste

Organic waste

Biosolids

Screwtech Launders

Conveyor Type

The Screwtech Launders’ primary function is to transfer fluids or slurries between processing equipment. Being part of the ScrewTech family, our range of Launders share common dimensions and standard parts with our Screw Conveyors. This enables continuity between associated system components, ie transitions, diverters, slidegates and screw conveyors.

Typical Applications