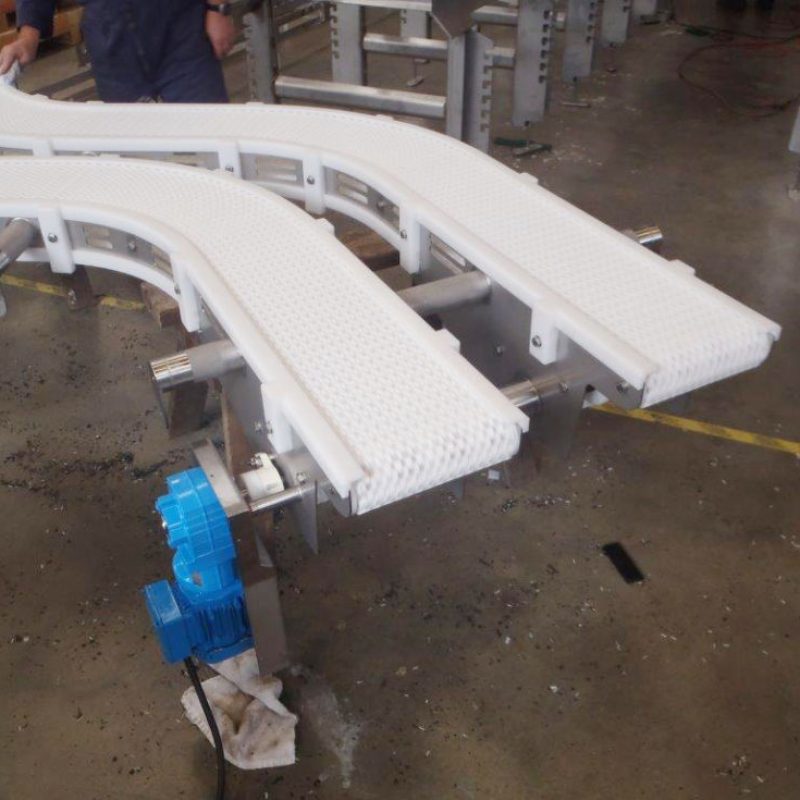

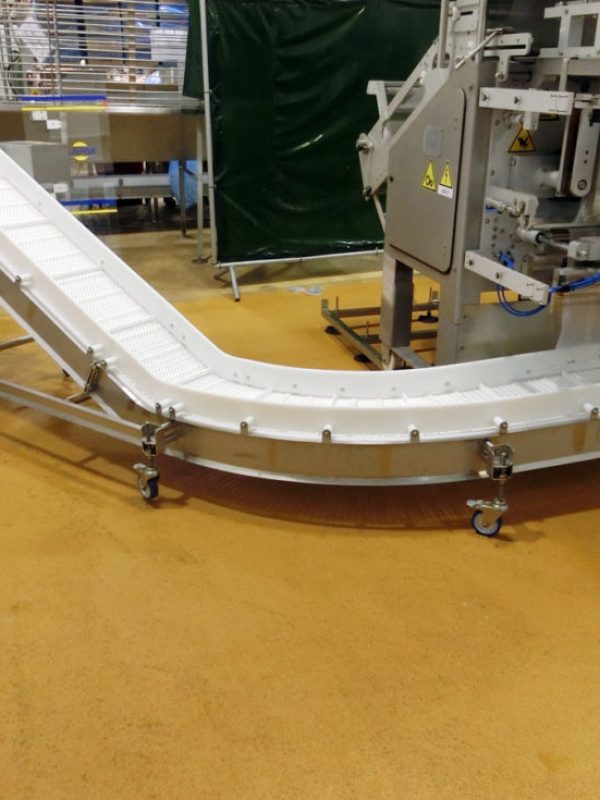

ModuLine is a unique modular belt conveyor design incorporating a range of standard modules to form a single stand-alone conveyor or a complete conveyor system. The ModuLine conveyor range can be specified to suit virtually any configuration, environment or conveyed product.

A feature of ModuLine is its ability to be easily dismantled and reconfigured if plant layouts or production requirements change. Modular sections can be simply added or removed at any time.

The individual modules feature clip-on components minimising fasteners. This design feature also allows worn or damaged components to be readily replaced ensuring minimum downtime.

Scroll down to view our range of Modular Belt Conveyors.

Typical Applications

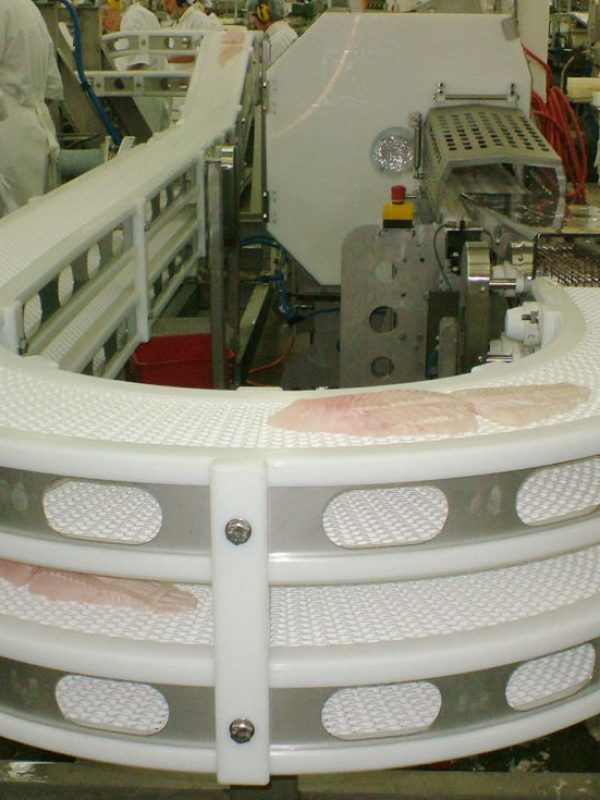

Seafood, Meat and Poultry

Fruit and vegetables

Bakery and Confectionary

Snack foods

Beverage

Packaged goods and cartons

Moduline

Modular belt conveyors

Conveyor Type

ModuLine is a unique conveyor design using modular plastic belt with a range of standard frame modules to form a single stand-alone conveyor or a complete conveyor system. The ModuLine range of conveyors has proven to be a versatile and economic alternative to custom manufactured conveyors. The ModuLine conveyor range can be specified to suit virtually any configuration, environment or conveyed product.

Features

- Individually hinged infeed/discharge sections for easy cord replacement and sanitising

- Removable nose roller assemblies

- Polymer bed

- Product side guides (optional)

- Manufactured from FDA/USDA materials

Typical Applications

Seafood, Meat and Poultry

Fruit and vegetables

Bakery and Confectionary

Snack foods

Beverage

Packaged goods and cartons

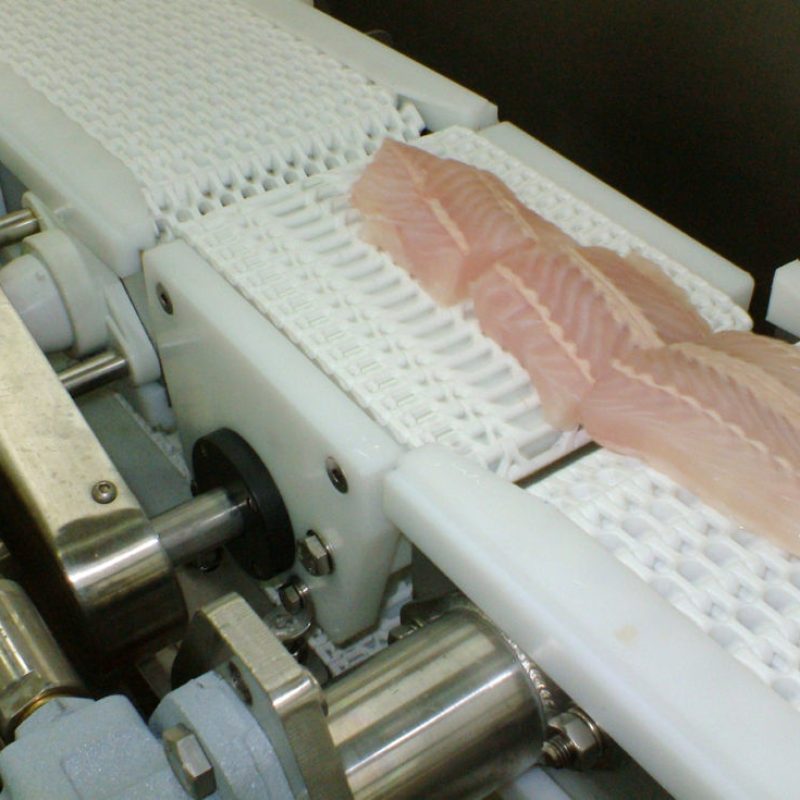

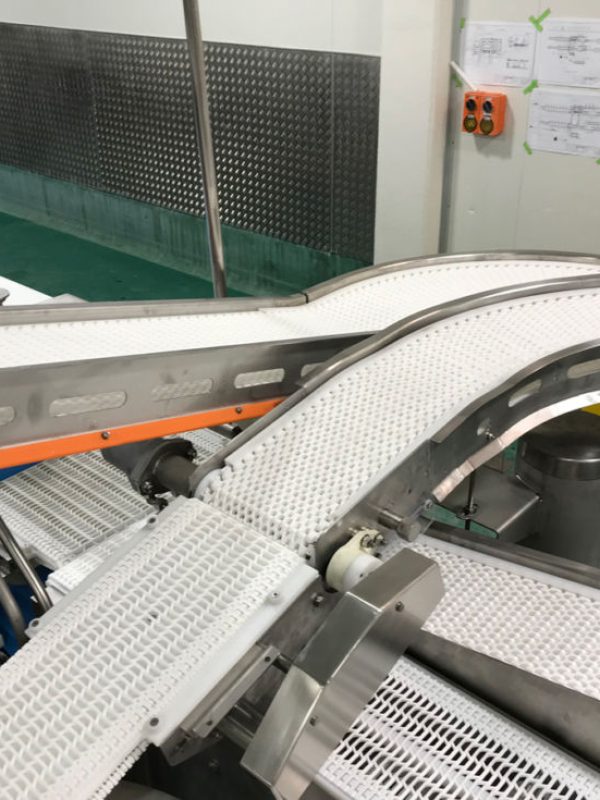

Moduline Hygiene Series

Modular belt conveyors

Conveyor Type

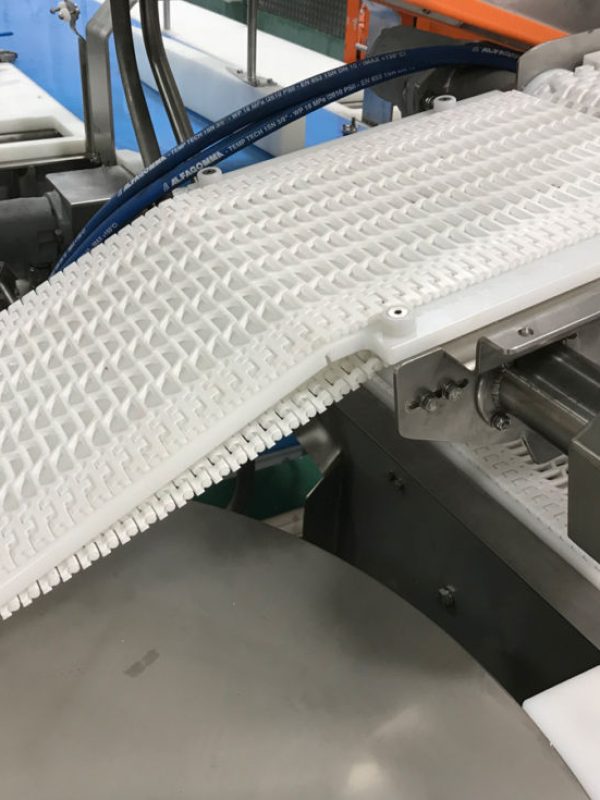

Just as versatile as the standard Moduline range the Hygiene series modular belt conveyor design enables easy sanitation features. Built with robust stainless steel chassis and clip in food grade plastic componentry. Other key features include integral CIP sparge lines, hinged end sections and belt lifter arms for easy cleaning.

Features

- Individually hinged infeed/discharge sections for easy cord replacement and sanitising

- Removable nose roller assemblies

- Polymer bed

- Product side guides (optional)

- Manufactured from FDA/USDA materials

Optional

- Critical hygiene conveyor construction with cleaning slots

- Integral CIP sparge lines

- Hinged infeed / discharge ends

- Manual or automatic belt lifters

- Multiple lane or multi-tier conveying options

Typical Applications

Seafood, Meat and Poultry

Fruit and vegetables

Bakery and Confectionary

Snack Foods

Loose bulk or raw products

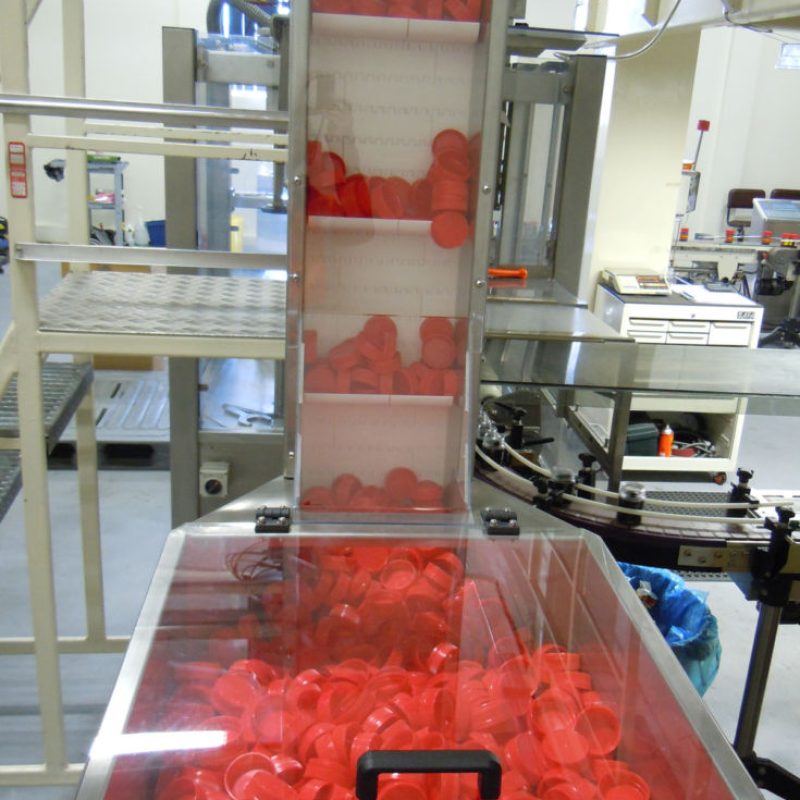

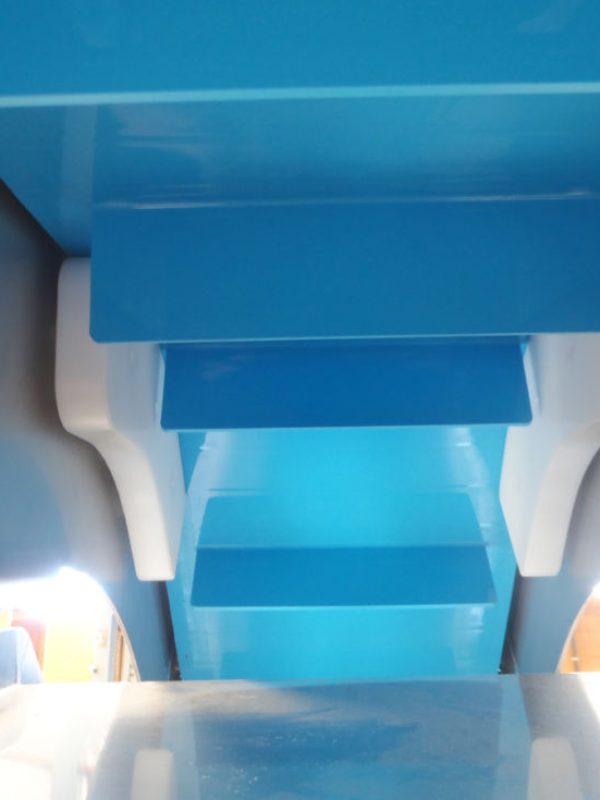

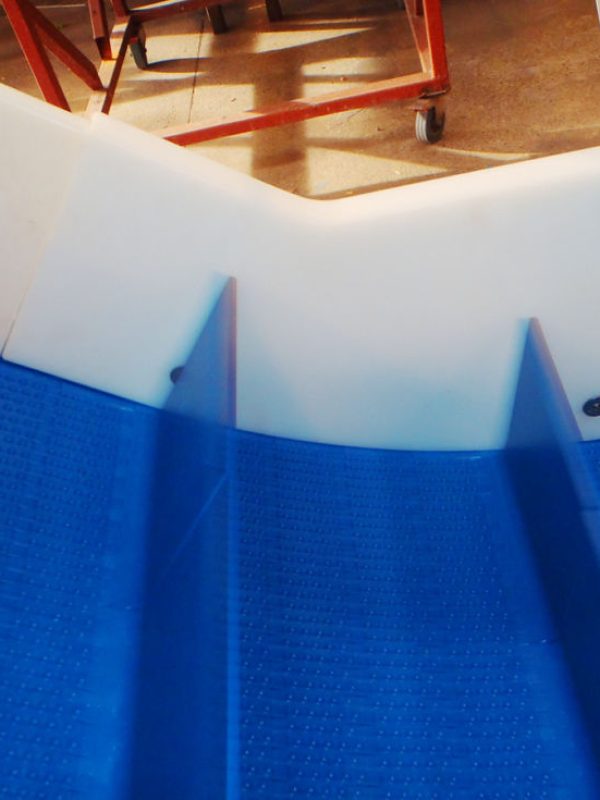

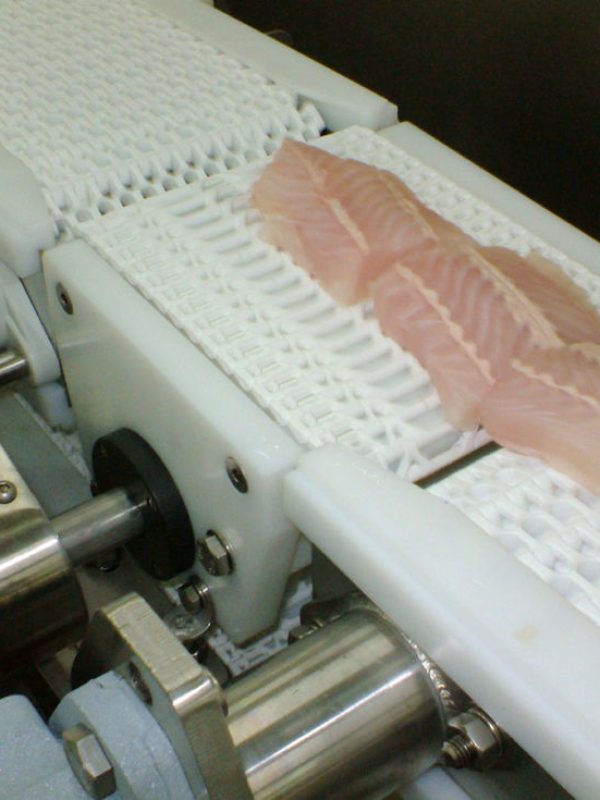

Eleveyor

Cleated Modular Belt Conveyors

Conveyor Type

Elevayor is typically based on the ModuLine method of construction and used to elevate or lower bulk or loose packaged products. With a vast array of belt attachments available allows Eleveyor to conveyor products at any angle.

Features

- Polymer belt carry and return guides

- Height and angle adjustable leg or hanger assemblies

- Product side guides – fixed or hinged

- Manufactured from certified Food grade materials

- Hygiene series options can be included

Typical Applications

Cooked, sliced, frozen and raw food portions

Fruit and vegetables

Packaged loose items

Snack Foods

Loose bulk products

Polydrive

Small Polymer Modular Belt Conveyors

Conveyor Type

Our Polydrive range of conveyors are best suited for short conveying, gooseneck arrangements or complete metal-free zones and provide a cost effective method of conveying over short distances. Polydrive range features machined plastic side plates with grooved track for the belt. Integral high side profiles enable product catchment and guiding. Non-metallic plastic cross bracing provide hygienic and simple construction.

Features

- Polymer belt carry and return guides

- Height adjustable feet or castors

- Product side guides – fixed or hinged

- Manufactured from certified Food grade materials

- Hygiene series options can be included

Typical Applications

Cooked, sliced, frozen and raw food portions

Packaged loose items

Snack Foods

Loose bulk products

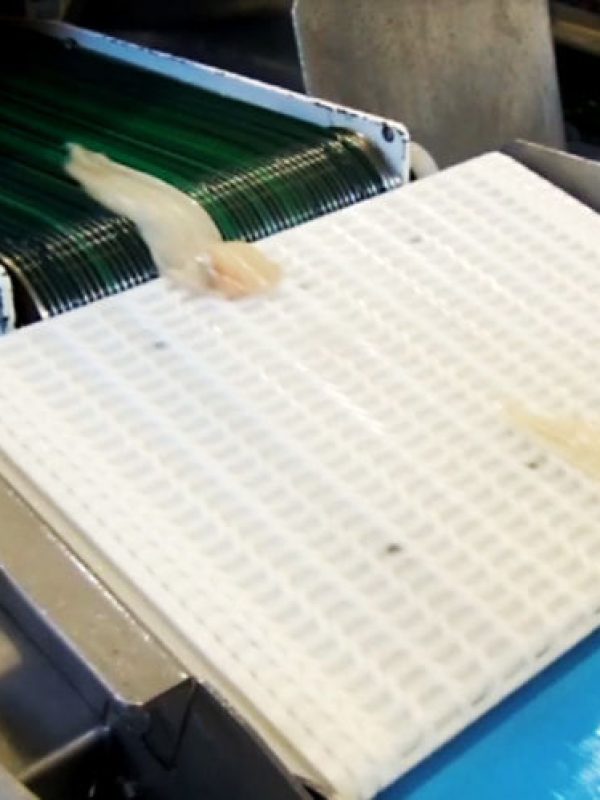

Livetranz

Live driven transfer Conveyors

Conveyor Type

Livetranz double nose bar transfer conveyors have been designed to replace deadplates between conveyors where irregular shaped or unstable products can hang up during transfer. Livetranz can be powered independently or slave driven off an adjacent conveyors and the simple design makes them a cost effective option for eliminating product damage and potential product jam ups.

Features

- Polymer belt carry and return guides

- Integrated or independent of parent conveyor

- Fixed or quick release conveyor chassis

- Manufactured from certified Food grade materials

- Direct drive or slave driven options

Typical Applications

Seafood, Meat and Poultry

Bakery and Confectionary

Fruit and vegetables

Snack Foods

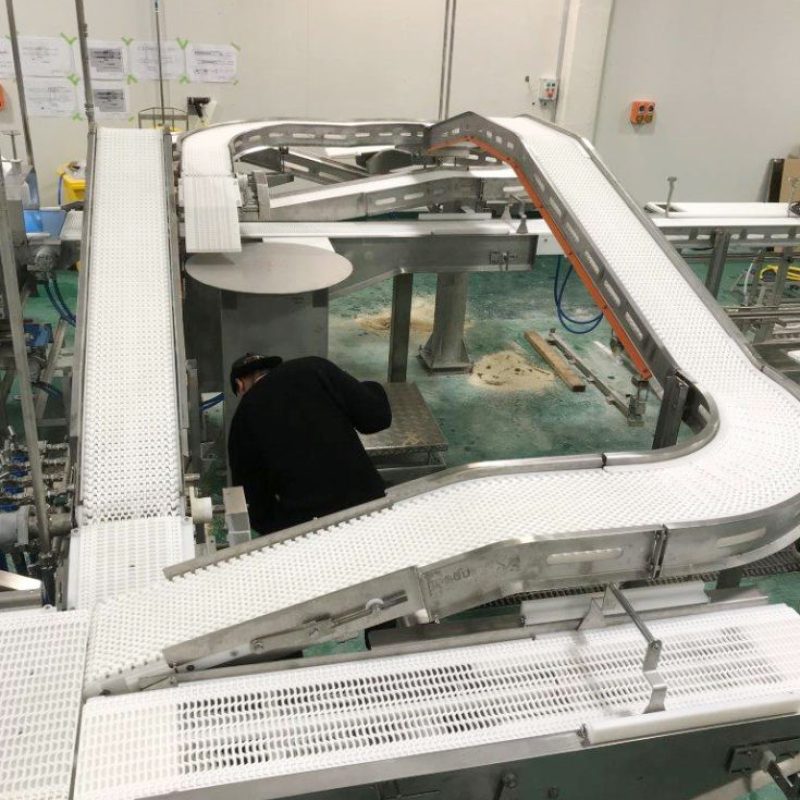

Parallel Carousel

Acculumation Conveyors

Conveyor Type

If product accumulation and a small footprint is a key requirement then the Parallel Carousel conveyor is ideal for your application. This twin lane conveyor utilises opposing belt flow direction and end fence guides to circulate the product enabling a simple solutions to your accumulation needs.

Features

- Each conveyor width and surface speed can vary

- Polymer belt carry and return guides

- Height adjustable leg assemblies

- Product side guides – fixed or hinged

- Pivot end guides and centre fences

- Manufactured from certified Food grade materials

Typical Applications

Packaged items

Cartons and containers

Bottles and cans