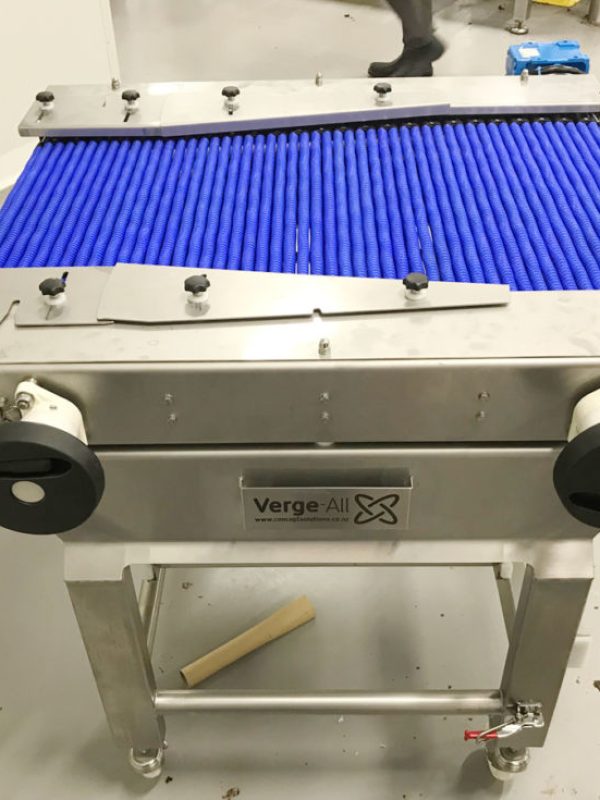

VergeAll

Converger or Diverger Conveyor

Conveyor Type

VergeAll is an inline conveyor module that converges and/or diverges loose product on a production line at production speeds. It is essentially a conveyor belt manufactured from hard chrome plated stainless steel rods connected to and driven by parallel drive chains. The injection moulded coil springs are mounted over the rods and between the chains. As the conveyor moves the coil springs pitch centres increases or decreases to effectively change the width of the conveyor which in turn changes the loose product centres.

Options

Applications for VergeAll are varied, but are commonly used in food processing plants to:

- Converge product to either increase or reduce cooling

- Converge product prior to packaging

- Converge product to reduce waste space created by wide process equipment

- Diverge product to create spacing to allow coating, enrobing or battering

- Diverge to prevent product contact during cooking

- Diverge to prevent product contact during cooking

Typical Applications

Frozen, cooked and coated products

Packaged products

Cut or sliced products

Polyband

Polyurethane Band Conveyors

Conveyor Type

Our Polyband polyurethane band conveyors design allows for quick release cords and belts are great for critical hygienic applications and easy maintenance. PolyBand can be integrated with any conveyor assembly to tier select or reject product to other lines or product streams. Polyband can manipulate the product orientation through any angle, ie narrow side leading entering the conveyor to wide side exiting.

Features

- Individually hinged infeed/discharge sections for easy cord replacement and sanitising

- Removable nose roller assemblies

- Polymer bed

- Product side guides (optional)

- Manufactured from FDA/USDA materials

Typical Applications

Baked Goods

Snack Foods

Packaged Product

Zero radius corners

Singuliser

Polyurethane Band Conveyors

Conveyor Type

The Singuliser is a stand-alone marshalling centre enabling multiple-laned product from a separate machine to be sorted/split and singulised to a single lane. The sequential control allows the Singuliser to capture and release index products one at a time to be converged downstream into a single lane.

Typical Applications

Packaged loose products

Itemise or singulise grouped items

Post wrapper or sealer machine

Modusort

Diverting Conveyors

Conveyor Type

ModuSort Stations enable high throughput automated carton diverting from a single transport conveyor. By integrating bar code scanning or other carton identification sensors the ModuSort can divert certain cartons to one or multiple conveyors at belt speeds of up to 50 metres/min or 60 cartons/min.

Typical layouts may include multiple ModuSort diverters with different cartons being diverted to specific packing areas. This flexibility offers many savings in labour units by delivering cartons exactly where they are being palletised.

Typical Applications

Single or multiple divert

Pack Room

Warehouses